Expert in steel processing

Maxilor is a company specialized in steel processing, with its industrial sheet-metal working, roll-forming and powder-coating equipment. Founded in 2008, it is established in Yutz (57- Moselle).

- Home

- Presentation

OUR BUSINESS SECTORS

The company is distinguished by the diversity of its complementary activities, grouped around 4 areas of expertise

Human commitment: Maxilor also stands out for its people-centred philosophy. Each employee plays a crucial role in the sustainable management of the company. They are responsible for social cohesion, the smooth running of production and the safety of all.

MAXILOR COMMITMENT

Reliability + Service + Speed + Quality = Customer satisfaction.

Maxilor is committed to meeting the requirements of all types of customers and projects, particularly in the fields of railway lines (LGV), the airport and warehousing sector, public works (TP), green spaces, and freeway and road equipment construction sites.

Technical resources : As a specialist in steel processing, Maxilor has high-performance, state-of-the-art facilities for laser cutting, punching, bending, mechanized welding, industrial painting, profiling and more.

Steel in shapes

MaxiLor’s slogan, “L’Acier en Formes” (“Steel in Shape”), reflects the ongoing enthusiasm for steel processing.

Its leitmotif, “He who does, knows”, underlines the importance of competence and action in the company’s culture.

OUR CERTIFICATIONS

ISO 9001

Maxilor is ISO 9001 certified, which means it complies with international quality standards in its manufacturing and management processes.

This certification guarantees that Maxilor implements quality management systems to ensure customer satisfaction.

ISO 14001

Maxilor has obtained ISO 14001:2015 certification for its environmental management system.

This standard attests to Maxilor’s commitment to protecting the environment and reducing its ecological impact.

The certificate is valid for the following products and services: design, production and assembly of metal products using mechanized welding, cold forming and powder coating1.

ISO 3834-3

Maxilor has also obtained EN ISO 3834 certification from the Institut de Soudure.

Label "LA FRENCH FAB"

Maxilor is proud to bear the LA FRENCH FAB LABEL.

This label highlights innovative, high-performance French companies in the industrial sector.

ECOVADIS GOLD

In March 2024, Maxilor was awarded the ECOVADIS GOLD distinction.

ECOVADIS evaluates the CSR (Corporate Social Responsibility) performance of companies, and the GOLD level testifies to Maxilor’s excellence in this field.

Démarche RSE de l’IUIMM

Maxilor is committed to a CSR (Corporate Social Responsibility) approach in collaboration with the IUIMM (Union des Industries et Métiers de la Métallurgie).

This approach aims to integrate responsible and sustainable practices into all its activities.

In short, Maxilor is a committed, certified and responsible company that places quality, the environment and customer satisfaction at the heart of its concerns.

CSR COMMITMENT

Maxilor’s commitment to Corporate Social Responsibility (CSR) is at the heart of our approach. Here’s how we put this commitment into practice:

Maxilor invests around 4% of annual sales in internal employee training, apprenticeships and/or work-study programs.

Safety at work

We organize regular safety training sessions for all our employees.

Environment

Every day, we take steps to reduce our carbon footprint through a variety of actions.

Partnerships with ESATs

For many years now, we have been working with two ESATs (Établissements et Services d'Aide par le Travail): ESAT Piennes 54 and ESAT Yutz 57. These partnerships enable disabled people to work in an adapted and rewarding environment.

Social cohesion

At Maxilor, social cohesion is essential. We regularly organize festive events to strengthen the bonds between our employees. These convivial moments foster team spirit and solidarity within our company.

Taking action for nature

We are proud of our on-site honey production. Our hives contribute to biodiversity and environmental preservation.

Sports Sponsorship

Maxilor actively supports young children's soccer teams. Our sponsorship enables these talented youngsters to develop their sporting passion.

At Maxilor,

At Maxilor, CSR is much more than a concept: it’s a reality rooted in our daily actions. We are proud to make a positive contribution to our society and our environment. 🌿🤝🏆

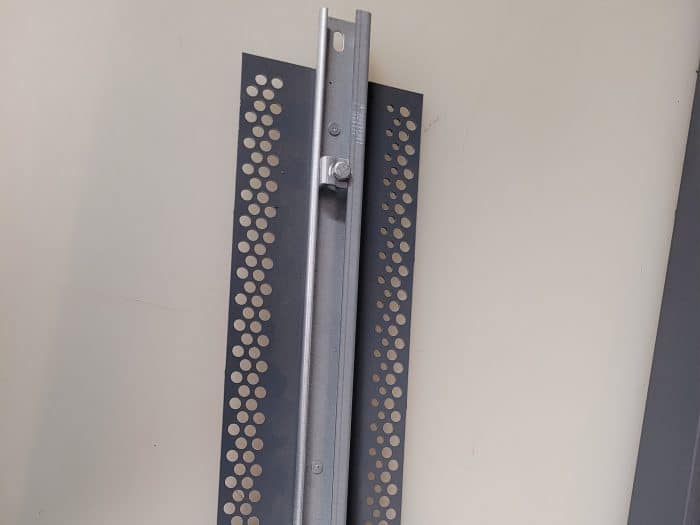

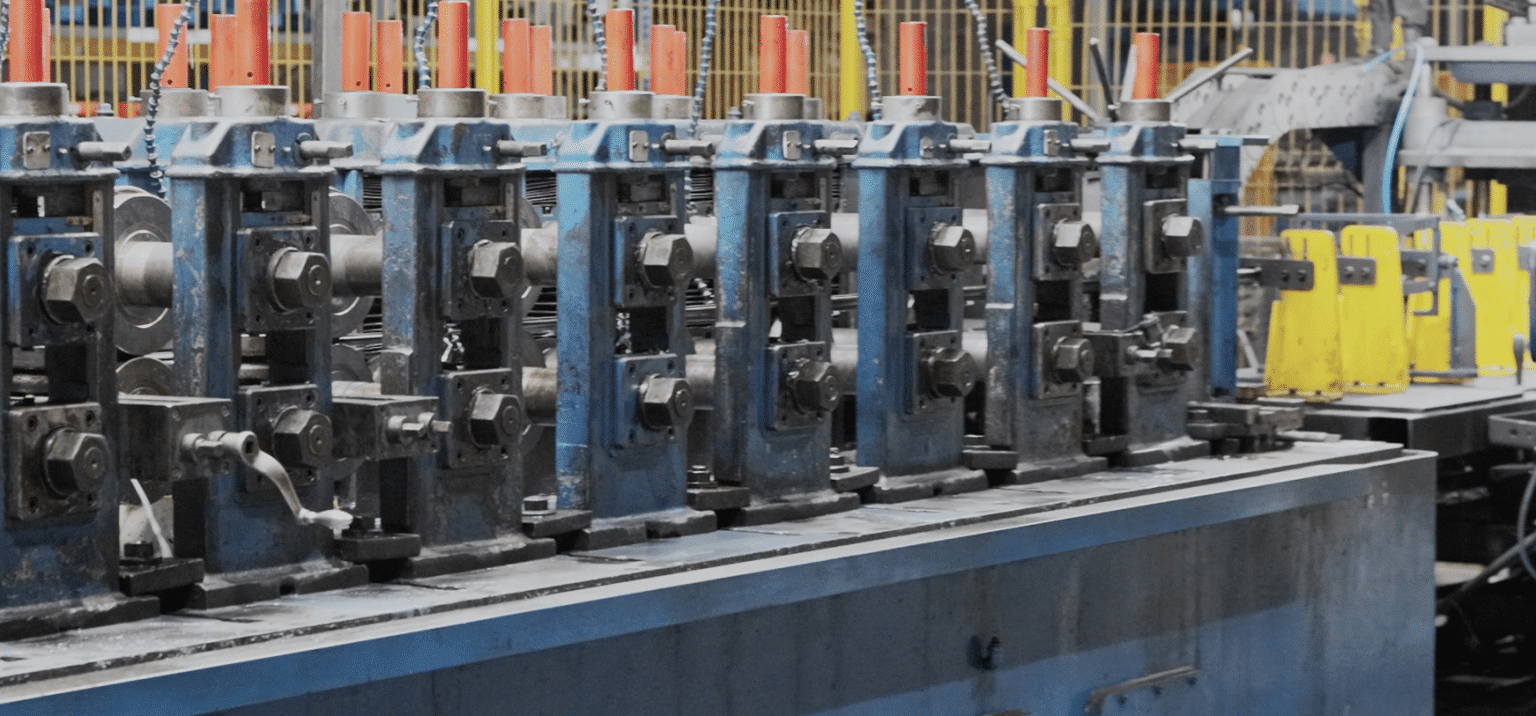

MAXILOR, STATE-OF-THE-ART EQUIPMENT

Maxilor uses state-of-the-art sheet metal equipment to ensure optimum manufacturing performance. These include high-precision laser cutting machines, CNC press brakes offering great flexibility, advanced welding robots guaranteeing consistent quality, automatic punching machines for increased productivity, and sophisticated dimensional control systems ensuring maximum precision.

These investments enable Maxilor to meet the varied needs of its customers while maintaining high standards of quality and efficiency in the production of sheet metal parts.

Fiber laser 2,000 x 4,000 mm with sheet magazine

Electric punching machine 1,500 x 3,000 mm with sheet feeder

Hydraulic bending machines up to 400 tons, 5m. With angle controllers and automatic tool changer.

TIG/MIG and automatic welding workshop.

Profiling line

Powder-coating line up to 6,000 mm long

3D modeling on Solidworks – digital production line